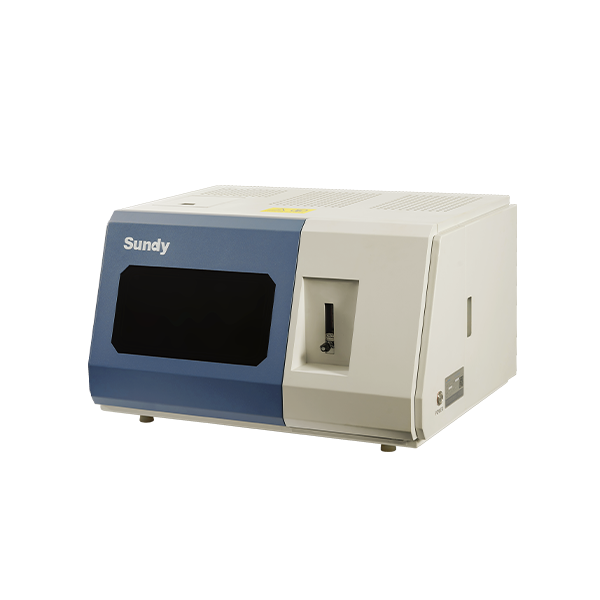

SDS-V Coulomb Sulfur Analyzer can be used to determine the total sulfur content in combustibles such as coal, coke, petroleum and other solid biomass fuels in the field of power plant, coal mining, cement & steel company, environmental industry.

①Optimized system design, complete sample combustion, full electrolysis of generated gases and thorough integration ensure accurate results. Specification:

②The integrated systems are pre-configured with hardware which can avoid errors with software integration effectively, More accurate and reliable results are delivered.

③Electrolytic cell location device and dilated and thickened platinum electrode plates ensure unanimous agitation and accurate test results.

④Reliable air pump adopted, longer lifetime and lower maintenance frequency can be obtained.

⑤Strong data processing capability by easy to use Windows-based software.

⑥Capable of connecting with network and balance by RS232 interface.

⑦With Ethernet communication technology, one PC controls several analyzers.Description SDS-V Test Method Coulomb Titration Sulfur Determination Range 0.01% – 40% Standards ISO20336,GB/T 214-2007 Sulfur Resolution 0.001% Analysis Time/sample 3 ~ 6min Preheating Time ≤30min Max. Quantity of sample 1 Sample Weight 10 – 110mg(50±5mg Recommended) Furnace Temp 1150℃(coal), 900℃(oil) ,1190℃(cement) Heating Elements Silicon Carbide Temp. Control Precision ±2.5℃ Temperature Sensor Thermocouple Power Requirement AC 220V(-15% ~ 10%)50/60Hz Max. Power 3.5kW Gas Requirement Air Gas pressure 14 to 45psig (1 to 3 bar) Sample Introduction and Discarding Manual Gas Flow Checking Rotor flow meter adopted Gas flow by visual check Chemical Reagents KI、KBr、Glacial acetic Humidity ≤85% Ambient Temperature ≤40℃ Operational Control Windows®-based software on external PC Operation Cost Lower cost Desiccant: allochroic silicagel Dimensions 680*520*395mm Weight 78kg Advance Calculation Yes Analysis Report Yes Statistics Report Yes System Monitor Yes

0086-731-88112150 sales@sandegroup.com

0086-731-88112150 sales@sandegroup.com

0086 731 88112150

0086 731 88112150 0086 731 88134650

0086 731 88134650 sales@sandegroup.com

sales@sandegroup.com